|

Working with Oak Continued

Here I'm drilling some clearance holes in the cleats that will hold

the bottom in place.

|

|

|

Once I had all the holes drilled and

countersunk, I clamped them in place and transferred all the holes like

I did before.

|

|

|

Here you can see the bottom is fastened in place and it fits really

good.

|

|

|

I used some #8 flathead screws to hold everything together.

|

|

|

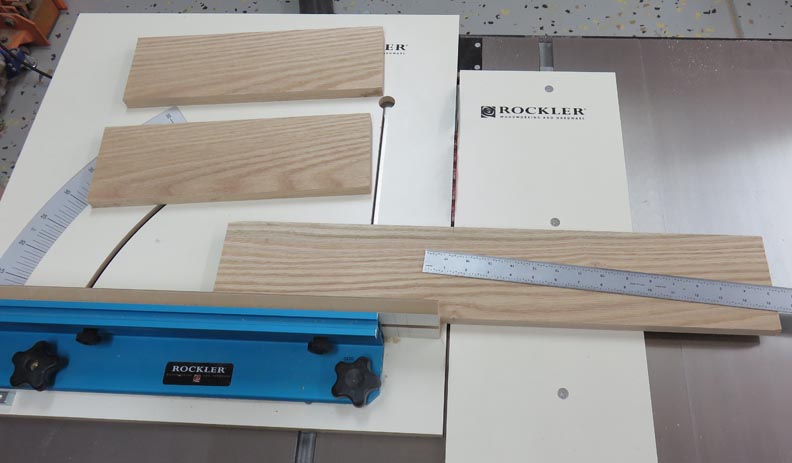

Now it's time to work on the lid. Here I'm cutting some pieces that will

become each side of the lid.

|

|

|

Next I glued my pieces together oversize and will cut them later.

|

|

|

|

Keeping Busy

While the glue was drying, I started making my plugs that will hide

all the screws that holds the box together.

|

|

|

Here is what I did in just a few minutes. And yes I realize this is way

too many but I couldn't help myself because of how easy it is to make

these.

|

|

|

|

Custom Ventilation

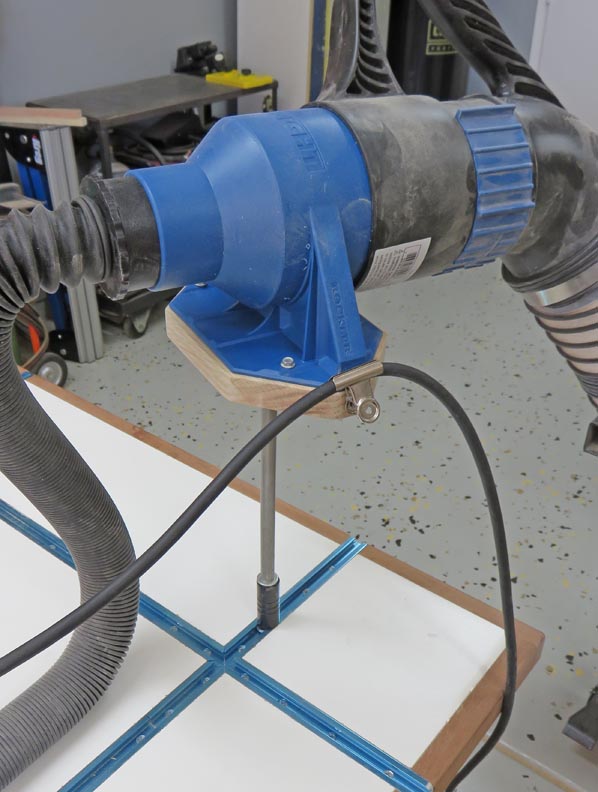

This is the latest in the way of dust collection, at

least it is for me. I bought the blue adapter and made everything else.

I even added a small clamp to hold the power cord for my sander. I

mean....why not!!

|

|

|

This worked out great but I do plan on cutting the hose just a

little shorter. With this type of arrangement I have virtually no

sanding dust in the air.

|

|

|

|

1

2

3

4

5

6

7 |