|

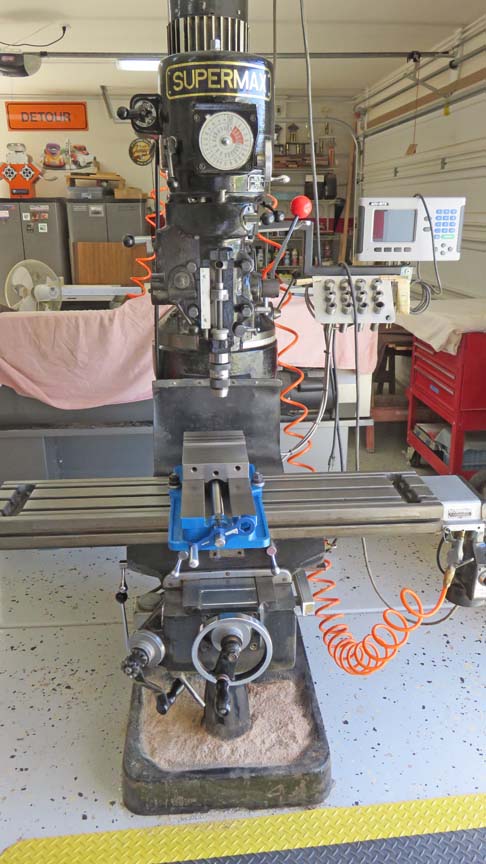

Supermax Milling Machine w/42" Table

I acquired this milling machine from my work in December

of 2012. It was gray back then but I painted it black a few months

later. I also bought a digital readout or DRO and installed it right

after I painted it.

As you can see it's made by Supermax, which is a clone

of the American made company 'Bridgeport'. Bridgeport mills are the

industry standard which work great and last for years. So far my machine has

been working pretty good, but I did take it apart when I first got it

and fixed a few things.

One other thing, trying to buy parts for this is almost

impossible anymore, and I've had to make a few things over the past two

years because I couldn't find replacement parts. This doesn't surprise

me because the machine was new in 1980 but the company went out of

business some time ago. The machine weighs about 1900

pounds and is very solid. And when a machine is solid, it works that

much better. Also, just like the lathe, this machine has a lot of levers,

handles

and dials as well.

|

|

|

|

The table is 42" long but they make models that are 49". However, this

table only travels about 23" in the X axis (left to right) which is more

than enough...most of the time. And like most older milling machines

like this one, it's

worn in the middle.

|

|

|

|

I bought this Kurt vise new right after getting the machine. I don't think

you can get a much better vise because these things work really great. It has

hardened jaws so they last a long time and the body is cast iron, just

like the milling machine. It also came with a work-stop that is stored

near the blue handle. Speaking of, that blue handle works

much better than the one that came with the vise because the other one

is very long and you can't spin it very fast. This blue handle on the

other hand can be spun very quickly, making it very easy to move the

jaw. The handle can be used like you see

below or moved to the outer position for more leverage. Kinda like

having your cake and eating it too.

|

|

|

|

The round handle on the right is for the Y axis (in and

out) and has about 13" of travel. I'll explain a little more about

this dial in detail below.

The long handle is to raise and lower

the knee. The knee is the large center piece, which encompasses the X and Y

axis. This is how you would set a precise depth of a drill or most other cutting

tools. Then you would reset the dial to zero (by loosening a lock nut) and

then turn the

handle your desired amount. Each full revolution equals

.100" so ten turns would equal one inch.

|

|

|

|

That round dial with all the numbers on it represents the rpm

of the spindle. The outer ring of numbers is for 'low range' and the

inner ring is for 'high range'. The small round handle to the right

moves the dial and changes the speed, but only when the motor is

running.

The handle at the top left is the power switch. Pull

that handle downward and the spindle turns forward while it's in high

gear. But when you change to low gear, you push the handle upwards to go

forward. Just little things you need to remember.

The handle to the left of the rpm dial is a brake. Push or

pull it and the spindle stops once you turn off the power.

|

|

|

|

To change from high to low range, there is a handle on

the side of the machine, which you can see to the right. And right

now it's in low range. This handle, like changing the RPM, only gets

moved when the motor is off.

The handle near the bottom is to engage/disengage the

feed for the quill. You might use this if you were boring a hole using a

boring head. All you do is pull outward on the handle and move it over

to the other hole and you're done. However, this handle can be moved

while the motor is running.

|

|

|

When the quill feed is engaged and being used, you have

three different feed rates to choose from. And yes you can change feed

rates while the motor is running. Again, you pull on the knob and place

it to

the feed rate that you want. The feed rates that you see below are in

"inches per revolution". Depending what the material that you're cutting

determines which feed rate you might choose.

See that small shaft sticking out at the right of the

picture? That's a small knob that changes the feed direction, either up

or down. Normally you would feed in the downward direction but if you

wanted, you'd pull on that knob and the feed would change.

|

|

|

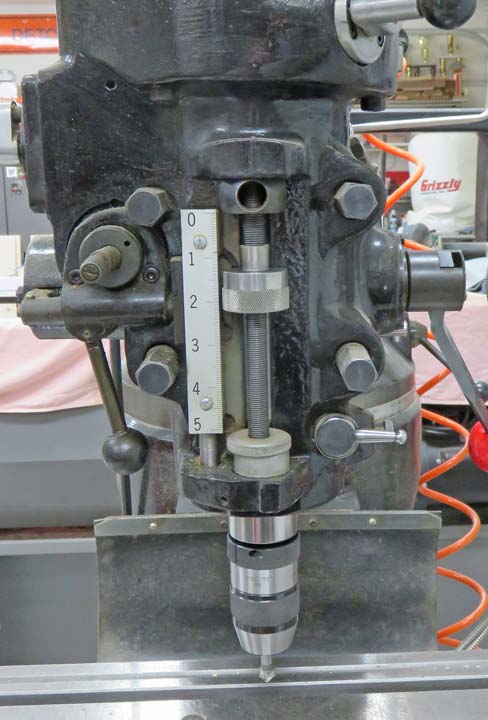

Here you can see that same shaft with the knob at the

end but looking straight at it (to the left). And this knob turns slowly

while it's engaged. Now to engage the feed for the quill, you push that

lever (below the shaft) to the left. And when the quill travels down to

that knurled nut (silver), it disengages the feed and the lever moves

back on its own.

|

|

|

Here is a close-up. That black piece with the hole in it

is attached to the quill. And when this comes in contact with the

adjustable nut below it, this moves the threaded shaft and disengages

the feed. Now when you're not using the feed, you can still use this

adjustable nut to set the depth of the quill. Say for drilling a hole,

or the depth of some other cutter. I've set this with a six inch scale

many times, if the depth isn't critical.

|

|

|

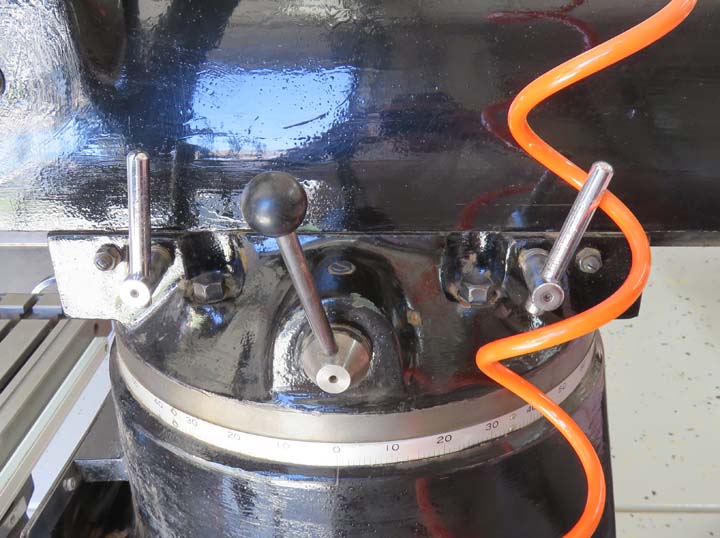

Those two chrome handles tighten or loosen the ram right

above it. The ram rides on dovetail slide ways and moves in or out when

you're standing in front of the machine. This is a very useful feature

to be able to machine different size work pieces.

The handle with the black knob moves the ram (that large

solid piece above them) once they're loosened. I use this feature all

the time depending on what I'm working on. The ram is what the spindle

head is bolted to.

See the two nuts between the chrome handles? There are

four of those, two on each side. I'll show you more on the next page.

|

|

|

|

Here is better look of the ram from the other side. Once

those two chrome handles are loose, you can move it with the lever on

the other side. The ram has about 12" of travel and I've used all of it

depending what I'm doing.

|

|

|

|

1

2 |