|

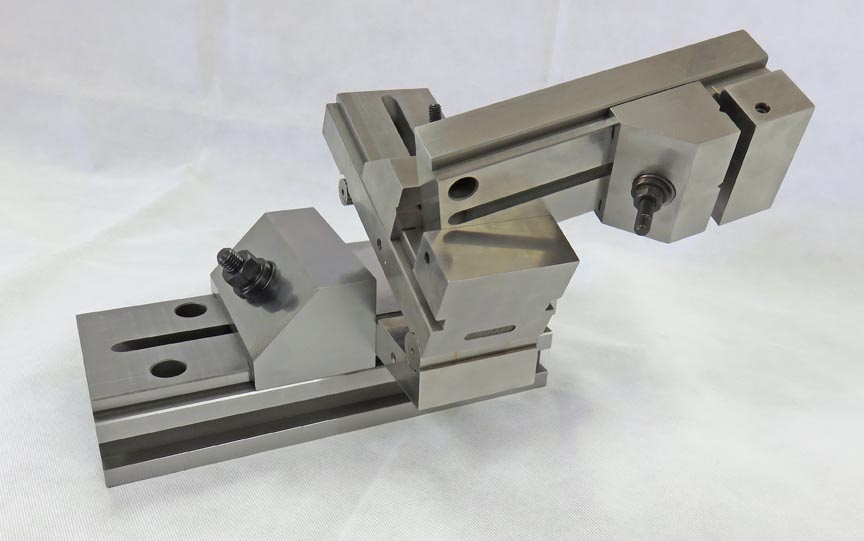

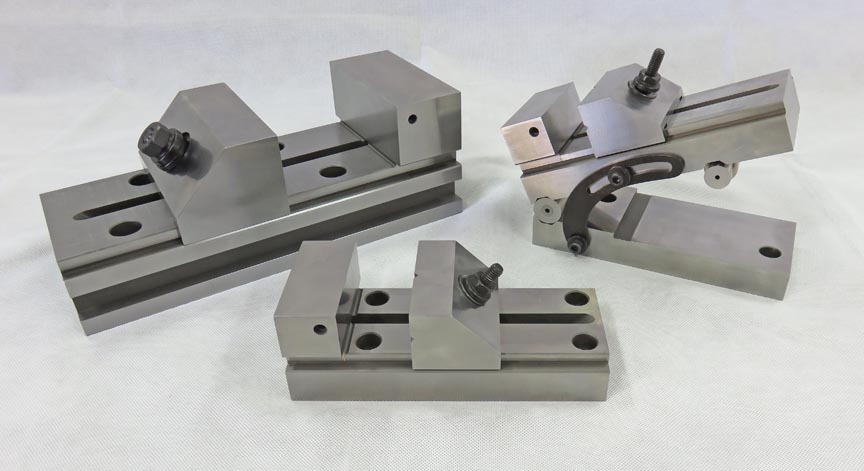

If this picture looks familiar, it's because I built the

two smaller vises on the

left back in

October of 2018 while the larger one sat all this time. But

now I finally finished it. This large one is 12" long and it's heavy.

Side note: if you haven't read about the first two vises, I highly

recommend checking that out before you go any farther because it

explains how this project came to be.

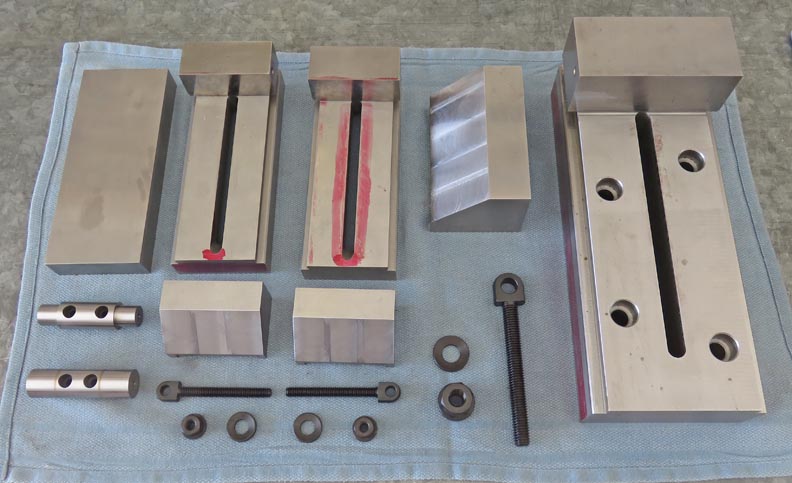

Once I sent all the pieces to heat treat, the slow

process of surface grinding begins. In fact, it took over11 hours

to grind the large vise which I spread out over a two week period.

|

|

|

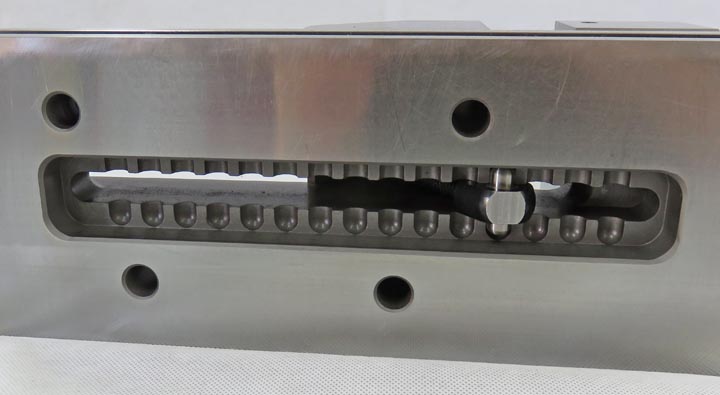

Here I'm using my sine plate to grind the

45 degree angle on the movable vise jaw. If you look close

you can see I've just started to clean up the surface.

|

|

|

|

Here is what it looks like all finished. However, I

wasn't able to grind every surface myself because the size of this vise

is larger than my works surface grinder could deal with. But I talked

with our neighbors because they have a larger machine so they helped me

out. They ground four surfaces for me, both ends, one side and the bed.

|

|

|

The key to any vise is how well the movable jaw fits and I took my time

when it came to this dimension because it fits great.

|

|

|

The holes that you see in the solid jaw is tapped with 1/4-20 threads in

case I want to use a work-stop.

|

|

|

|

Here is the bottom which has all the notches for the

movable jaw. The four large holes are for bolting the vise to the mill

table, just in case I want to. Better to have them and not use them than

not have them at all.

|

|

|

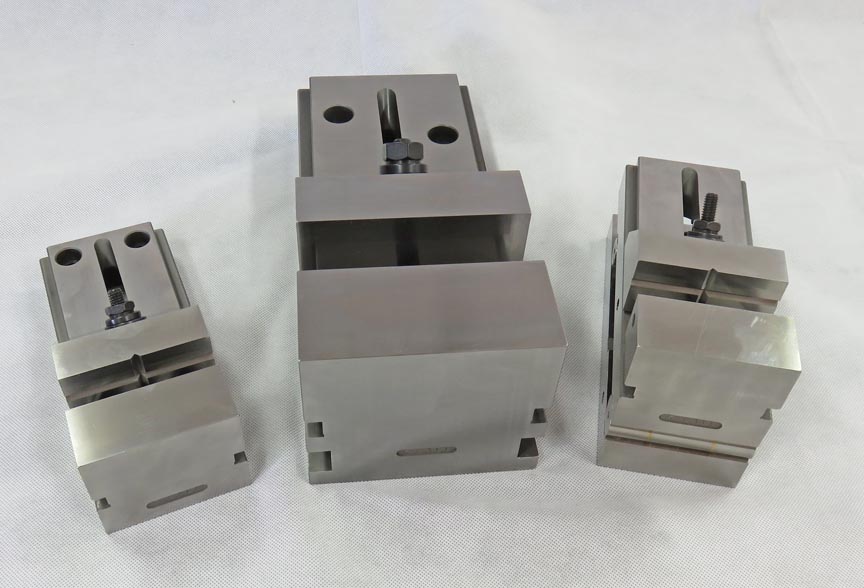

Here are all three finished vises.

|

|

|

I'm happy with how they all came out because they all work great.

|

|

|

Yeah, I know I'm trip'n here...

|

|

|

I'm looking forward to using the new one as much as I've used the

others. And after 36 plus years, I can finally say they are all

finished.

|

|

|

|

|