|

Working With Steel Continued

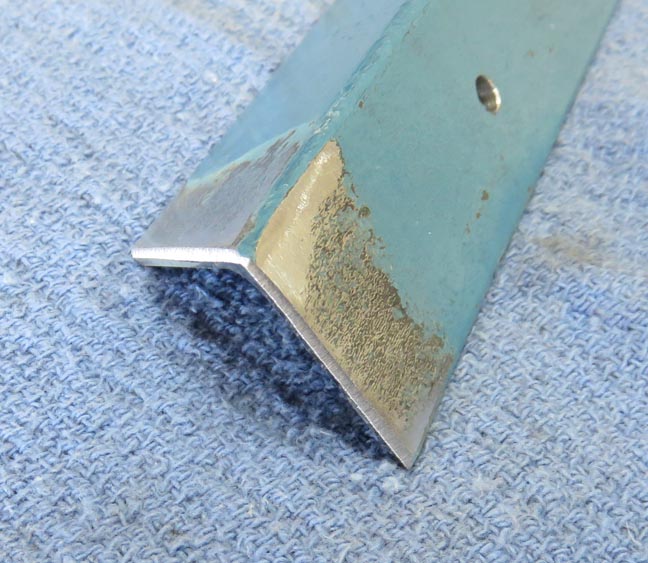

Now that the screw holes are in, I'll need to weld all

these pieces together. Below you can see I've put a small chamfer on the

end. This is called a 'weld prep'. When welding two piece together that

will have what's called a 'butt weld', (when two pieces get welded

end-to-end), you want to make sure the weld penetrates deep enough to

have

a strong weld. And by putting a weld prep on each piece, this makes sure

there is enough weld to hold things together after grinding the weld

down flat.

|

|

|

I tried using clamps to hold my pieces in the right

spot, but in the end I used some strong magnets that kept my work pieces

right where I wanted them while I tacked everything together. And I even

used one of the magnets to hold my ground clamp in place, which worked

great!

|

|

Here is a close-up of the tack weld and magnet.

|

|

|

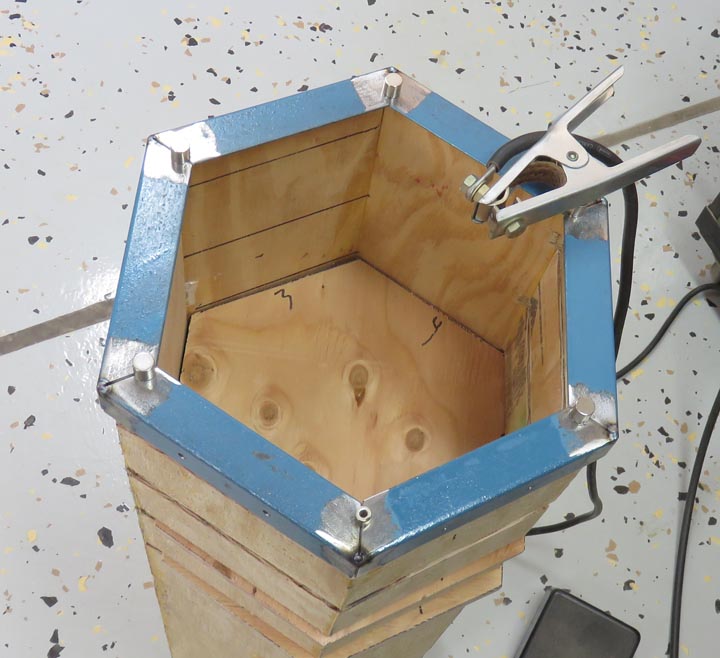

Once all the pieces were tack welded, I came up with a

way of holding my work piece while I fully welded each section. The

clamp on the left is holding a piece of scrap steel that my part is

resting on. The clamp on the right is where I placed my hand while I

welded. Whatever works ya know....

|

|

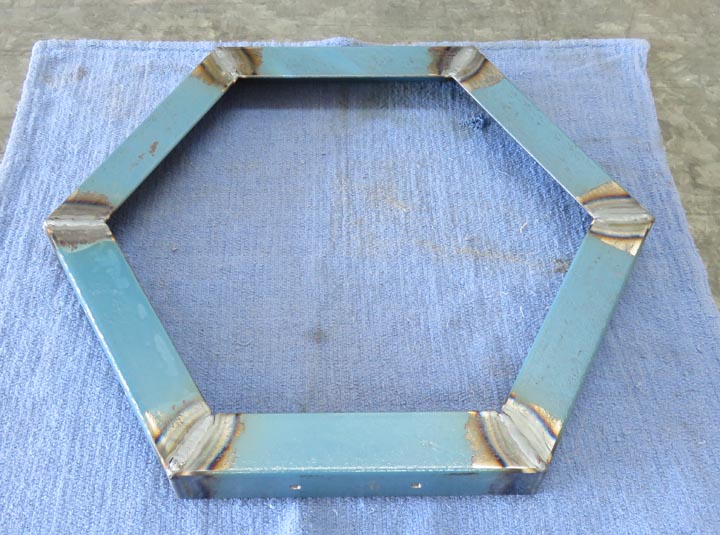

And there we go, it's all welded together.

|

|

Next I ground all the welds flat and I also used my file to hit some of

the sharp edges. That about does it for this piece and now it's time to

make three lower pieces that will also be hex shaped.

|

|

|

Like I said above, I'm making three hex shaped rings

that will be fastened to the wooden tower like the other one. I drilled a

clearance hole for the same size screws, and the ends have the same 30

degree angles on them. Think of these edges as a mitered corner and you'll

get the idea.

|

|

|

I used some .010" thick paper that I cut into strips

which I'm going to place under each piece while I tack weld them

together. This should provide enough clearance between each hex piece

and the wooden tower once I'm finished welding.

|

|

Here I'm tack welding the hex ring and I'm using a bunch of clamps to

help me. The paper is under each metal piece.

|

|

I could only clamp four pieces at a time, then I would remove one clamp,

position another metal piece and clamp it into place. This was a slow

process but it worked out.

|

|

|

1

2

3

4 |