|

Working With Brass Continued

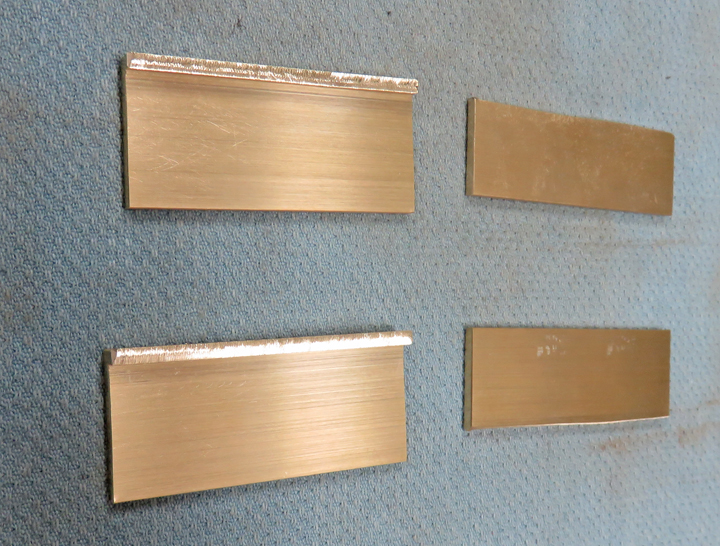

I'm getting ready to layout the contacts for the handle below. The

contacts that I'll use are the angled pieces that I just machined on the

previous page.

|

|

|

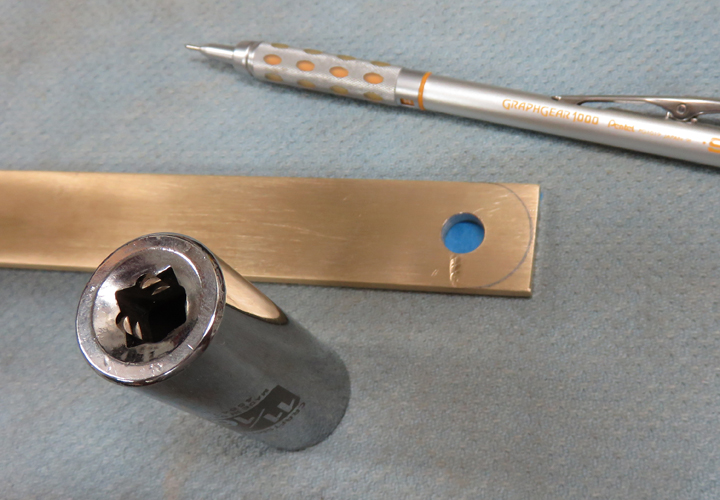

I'm drilling some oversize holes to use

with some 1/4-28 hex head bolts. These bolts will hold the angled pieces

(contacts) to my wooden box.

|

|

|

|

One end of the handle will need to be hinged so I'm

drilling some 3/8" diameter holes in the contacts that will used with 5/16"

shoulder bolts. This may sound like a typo but hang in there and it will

all become clear soon.

|

|

|

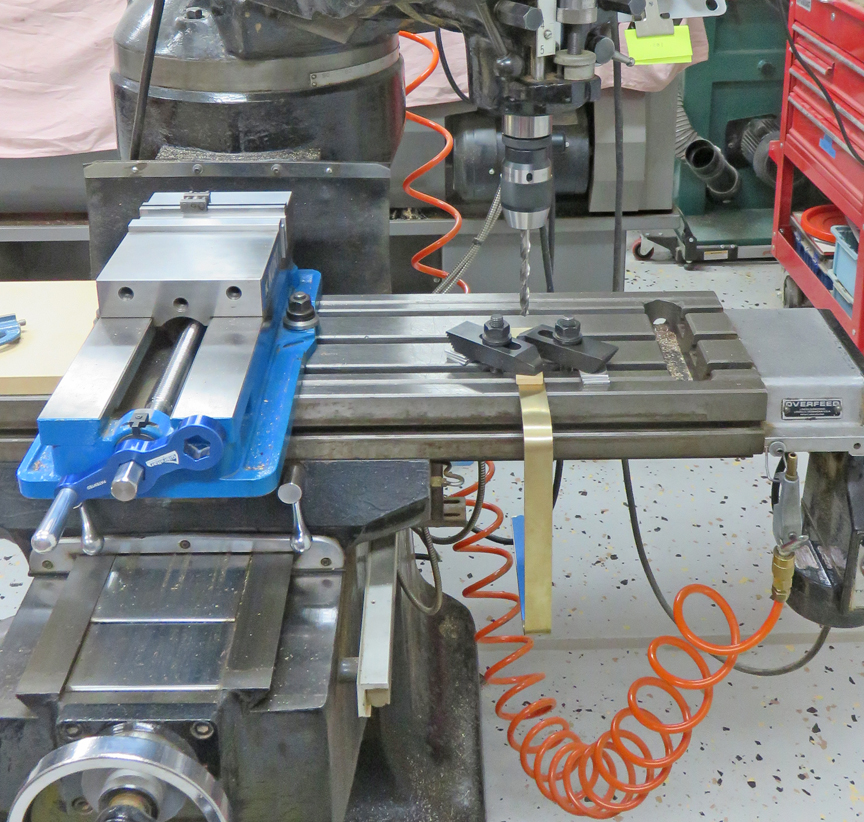

To drill the same size 3/8" hole in the handle, I had to swing the head

on my milling machine to one side. Then I clamped the handle to the

table while using the tables T slots to drill into.

|

|

|

|

This was an easy setup and was necessary so the holes

were

perpendicular to the surface. Could I have drilled this hole while it

was being held in my bench vise using a hand drill? Sure, but doing it

on the mill ensures the hole to be round and in the right location.

|

|

|

Here I'm laying out a radius so the handle will pivot from top to

bottom. I used my belt sander and sanded to the line. Quick and easy!

|

|

|

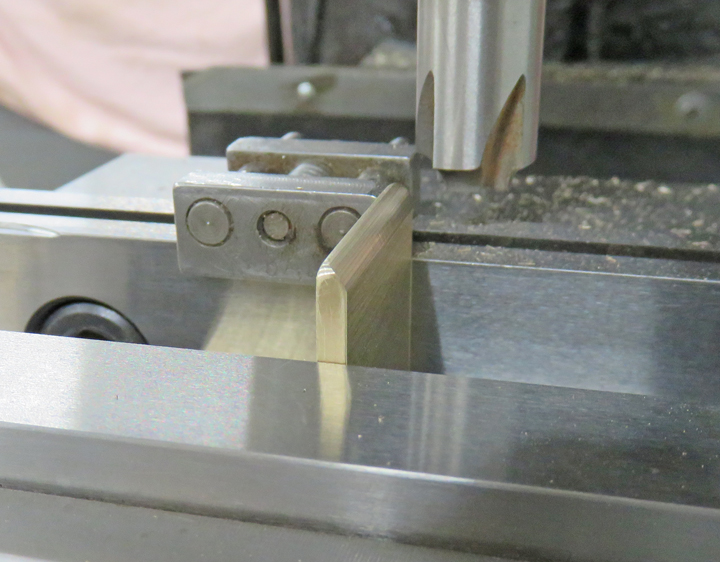

I'm putting a 1/8" radius on the contacts which will be at the top of the

switch. This way when the handle is getting ready to enter the upper

contacts it will help to guide it in.

|

|

|

|

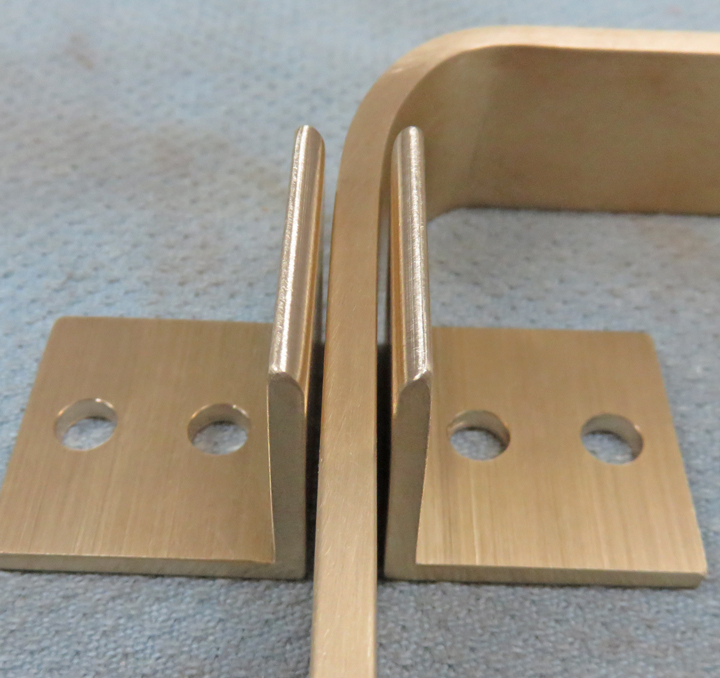

This should help give you a better idea of what I'm

talking about. One more thing, see how the handle is resting on the blue

towel along with the contacts? This got me thinking, because this is

what it might look like once everything is bolted to the wooden box.

However, this isn't ideal because that means the handle will constantly

come in contact with the box and might eventually put a mark on it or

put a dent in it. Well, we can't have that so let's make sure that

doesn't happen.

|

|

|

|

What I needed was a piece that would go underneath the

two upper contacts so the handle would rest on metal in place of the wood

box.

What I came up with was to cut a piece of the angle that I would machine

so it would be the same width as the other angle pieces, accentually

becoming a shim.

|

|

|

I machined the saw cut edges flush with the top surface and drilled four

holes to match the other two contacts. However, I forgot to take a

picture of the finished pieces but I'm sure you get the idea.

|

|

|

|

1

2

3

4

5

6 |