|

Working With Metal

This Yoga mat rack needs a place to hold some mats and

after talking with my daughter, she wants this part to be made out of

metal. I suggested using 1/4" diameter stainless steel bar stock for a couple

of reasons: first, I didn't want mild steel because it would eventually

rust. And yes, I could paint this mild steel but I didn't want it to

possibly transfer any paint to the mat.

Now depending on what type of stainless steel gets used, it

could rust too. Yes, stainless steel can rust depending on which type is

being used, so I need to choose wisely

here.

Note: if the stainless steel can be heat treated, it

probably has enough iron in it to rust. Material like 13-8 PH or 17-4 PH or

440c can all be heat treated and are some of the better stainless steels

out there. On the other hand, some of the 300 series of stainless steels

are perfect for my application because they won't take a conventional heat treat.

What I chose to use is 304 stainless for this project and each

piece will be cut and machined to 22" long. I bought two six foot lengths and I

should be able to get three pieces out of each length. What I'm doing

below is sanding each piece to give it a uniform finish first.

|

|

|

|

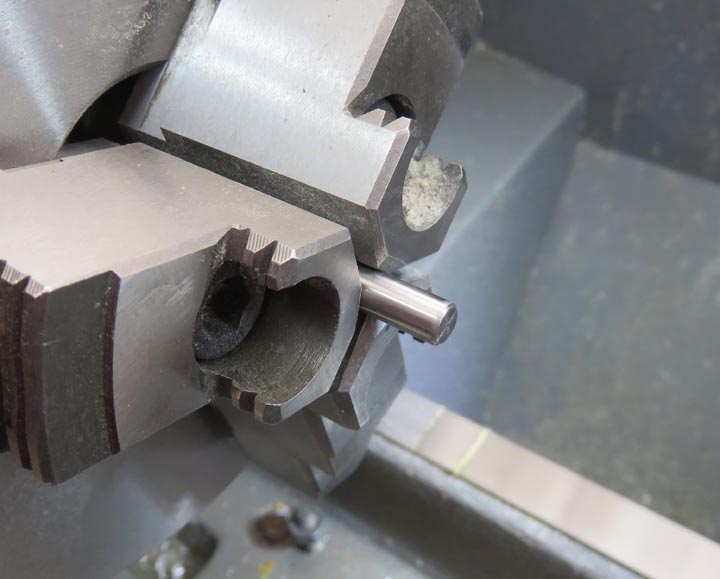

Then I machined each end and put a small chamfer on them

as well. The chamfers will make it easier to install them into the wood

later.

|

|

|

|

Tooling

What I want to end up with is a four inch radius (eight

inch diameter) for these racks, so I'm practicing with some scrap

material, bending it around my lathe chuck of the same size. However, as

you can see it has some 'spring-back' which makes the radius too large

for what I'm shooting for. Time for a different piece of tooling.

|

|

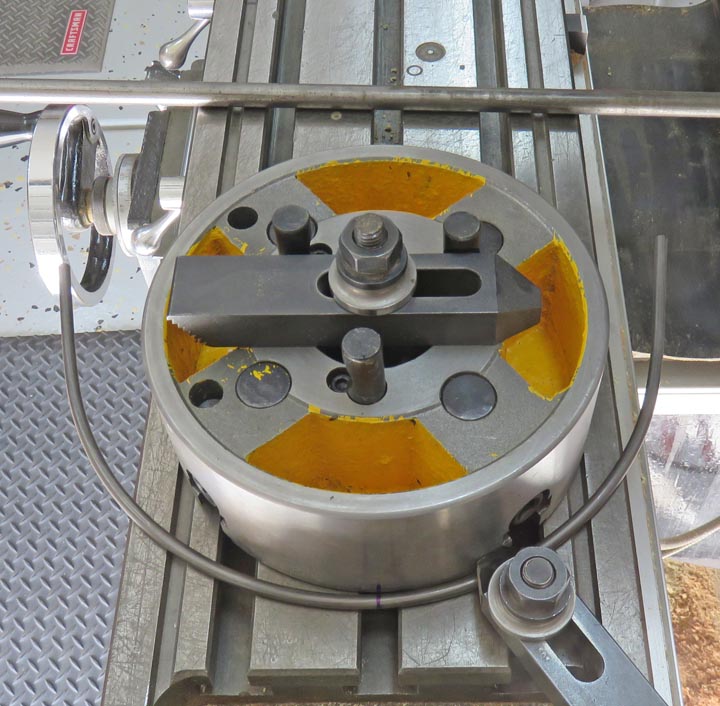

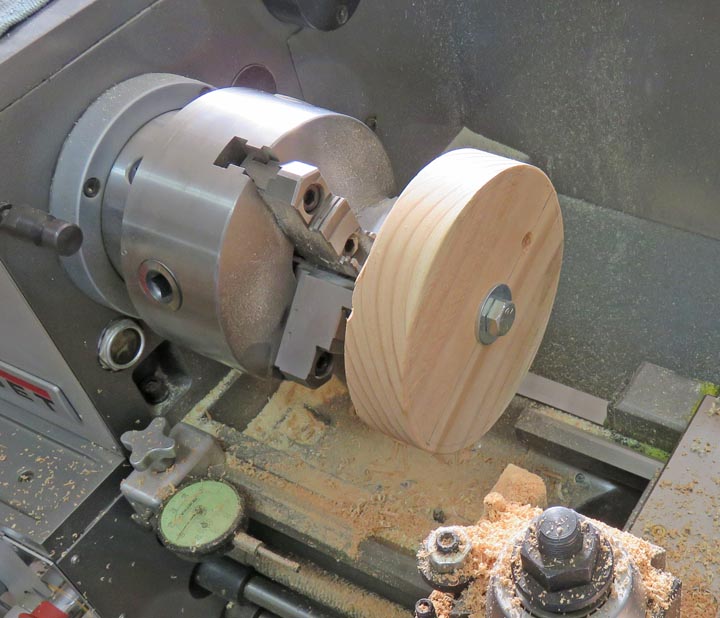

I decided to make some tooling out of wood, out of a 2" X 8" to be exact. The size

will be six inches in diameter but with the spring-back it should be

just about right.

|

|

|

|

Working With Metal Continued

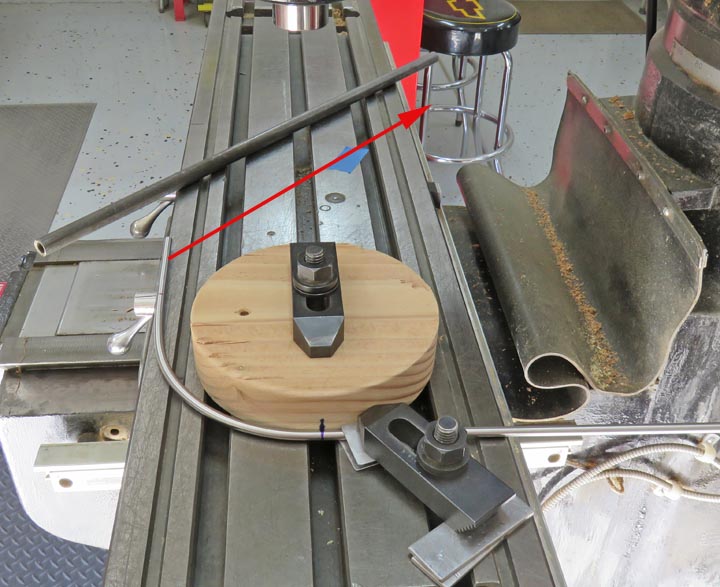

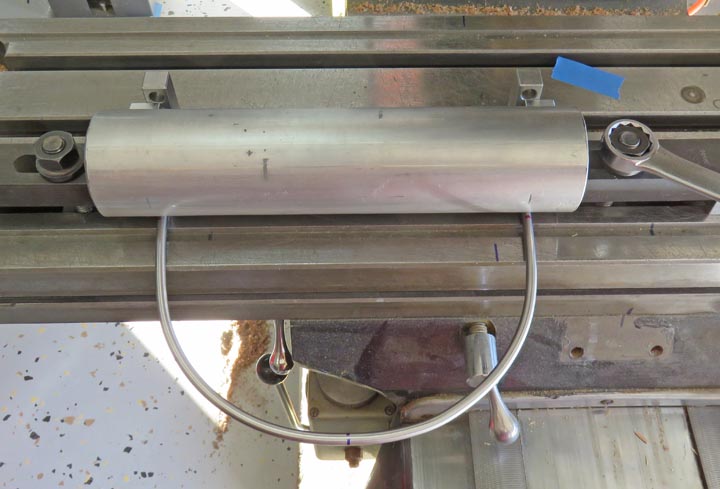

Here I'm bending the 304 stainless steel to see how much

spring-back I'll get. And it turns out this new piece of tooling worked

perfect. The piece of tubing on the mill table was used to help bend the stainless

(for leverage). I

slipped the tubing over the bar stock by about three inches and then

bent it around the wood piece to the angle of the red arrow. Once I

relaxed my work piece, it moved back to what you see below. That's called

'spring-back'.

|

|

|

|

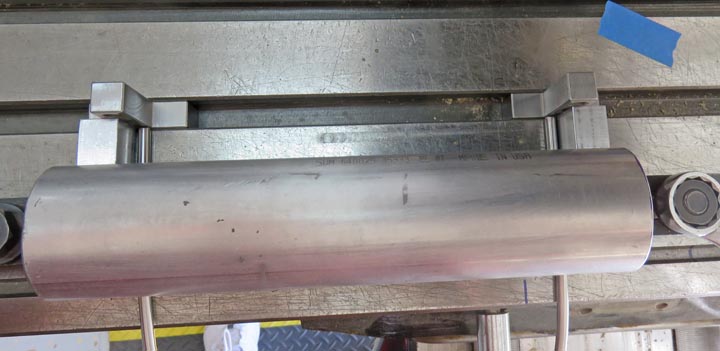

To line things up, I found the center of my work piece,

put a blue mark on it and aligned it with the same color mark on my wood

tooling, clamped it down and then bent it. Then I loosened the clamp,

turned my work piece around and repeated the process. This gave me a U

shaped piece, which is what I wanted.

Notice the aluminum shims on both sides of the stainless

steel. This is to keep my work piece looking nice after clamping.

|

|

|

|

After all the first bends were done, it was time for the

second bend. And for that I'm using some leftover 2 1/2" exhaust tubing

from my 33 Ford. As you can see I have the 1/4" diameter work piece

under the tubing clamped down from each end. This tubing will give me a

slight radius instead of a sharp bend.

|

|

|

To make sure all the bends are in the same location, I have my work

piece positioned against some work stops.

|

|

|

I squatted down and pushed upwards on my work piece until I had the

desired height that I needed. This was easy to do and it didn't take

long to bend all my pieces.

|

|

|

Here you can see the bend a little better, along with the clamps holding

everything down. This worked out great and it put a nice radius on my

work piece.

|

|

|

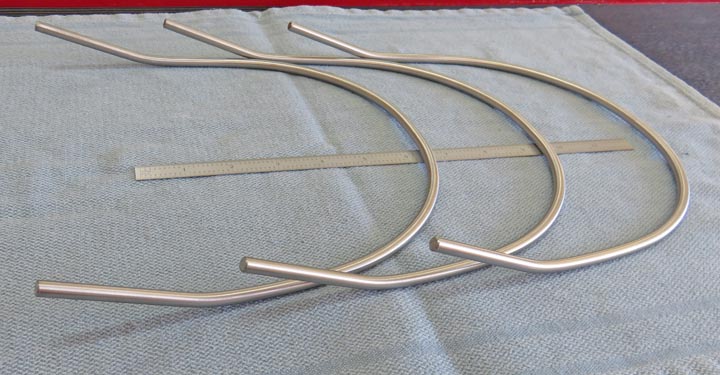

Here are all my pieces, but I did make one extra

just in case I messed up.

|

|

|

|

1

2

3

4

5

6 |