|

Working With Metal Continued

With the all the straight lines machined, it's time to address the

radii in the corners. BTW, the thickness of the sides are 1/2" with the

1/4" holes in the middle.

|

|

|

With only four areas that need work, I

used a file and worked to the line.

|

|

|

This didn't take long and it worked out great.

|

|

|

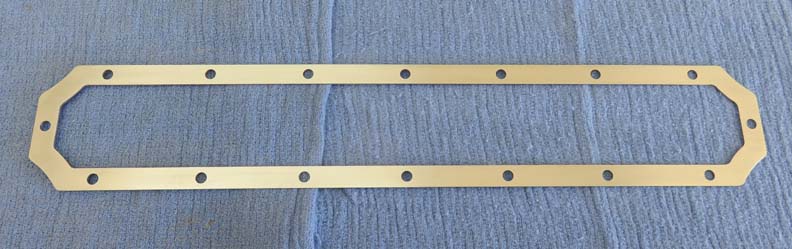

Here is the finished work piece that will be fastened to the top of the

wood.

|

|

|

A close-up of one end, which I'm happy with. Now it's time to work

on the wood piece again.

|

|

|

|

Working With Wood Again

If you remember the wedding present I made earlier, this will be the

same concept that I did before. I'm going to drill and tap the wood for

some 1/4-20 threads. First I'll use a center drill, then the tap drill

size and then finish with the threads.

|

|

|

|

Here I'm drilling all my holes and getting ready to put threads in each

one. I hand tapped each one in place of power-tapping with my milling

machine. The reason is because I have no idea how that would've turned

out so I was being cautious.

|

|

|

Next I used a pencil and traced around my metal piece giving me some

layout lines to work with. Then I used my bandsaw to cut near the line.

|

|

|

|

Next I fastened the metal to my wood base and used a flush-trim bit on my

router to finish the four corners. A keen eye will notice the metal is

above the wood surface. I used some washers between the metal and wood

to give me some separation for the bearing to ride on.

|

|

|

This only took a few minutes and after a quick deburr with some

sandpaper, the wooden part is almost finished.

|

|

|

|

1

2

3

4

5

6 |