Making Changes Continued

Here you can see that I've just started turning these pieces. If you look

close you can see the sharp corners are gone now and the parts will soon be

round.

|

|

|

Here are the 11 pieces nice and round and now they will

need to be deburred. Notice the pin doesn't exit the parts here. This

way the washer is held against the parts only and the pin is out of the

way. I figured out how long the pin needed to be and then cut it to

length so it fits like this. On a side note: I just happen to have a large enough washer that

would work with this setup so I didn't have to make a custom one. Lucky

me!

|

|

|

I did the deburring on my belt sander which was quick

and easy. Now they will need some paint as Matt and Angela didn't want things to look very modern,

but I'll get to that later. On the other hand,

I personally am all about

contrast and not having everything blending together. But this is their

project so whatever the boss wants, the boss gets :-]

|

|

|

Back from Plating Here are all the gears back from the plating shop. They came out pretty

nice and the kids are happy with them. The one with the 12" pitch

diameter that you saw

earlier is at the bottom right. Now it's time to put these aside and

keep them clean until I need them.

|

|

|

Chains And Sprockets

Awhile ago I mentioned there would be some chains, and

to move those chains I'll be using sprockets. There will be three sizes

of sprockets,

two 4" (below), one 5" and three 6". I'll be using a total of six

sprockets but two of them will be paired with gears. This 4" sprocket

that you see below has a 1/2" diameter hole in it. This hole is the same size

as all the shafts but the other two sizes (5" and 6") have an odd size hole

of .594" diameter. The oversize holes in these larger sprockets are

something I'll have to address because I found out when I was buying all

the sprockets

that once you get larger than 4 inches in

diameter, that's when the hole diameters increase. In other words, having

oversize

holes in the larger ones were unavoidable.

|

|

|

The only machining that I'll do on the 4" sprockets

is putting a keyway in it. This keyway, along with a key, will be used with the

corresponding shafts that will

drive the sprockets. I'm using an 1/8"

end mill here to cut the keyway, which will be 1/8" long X 1/8" wide.

I'll talk more about this size in a minute. To cut the keyways I used an

indicate to find the center and then machined them. This is a simple

operation and it went quickly.

Side note: the aluminum plate under the sprocket

is used as tooling and is sacrificial. When using a cutter that pass's

through your work piece (or drilling), you need something to cut into

other than your mill table. If you look close you'll see many holes in

this plate as it's been used for this many times over the years.

|

|

|

Here is the finished keyway in the 4" sprocket. The shaft

that has the keyway in it measures 1/8" wide by 1/16"deep. With that

size keyway you would normally use a key that measured 1/8" X 1/8"

(1/16" deep keyway in the shaft and 1/16" deep keyway in the sprocket).

However when I had the gears made by my water jet guy at R.I.

Industries, I drew the gears with a keyway size of 1/8" X 1/8". This

meant the key material would need to be 1/8" X 3/16" to fit correctly.

However this was something I planned on awhile ago.

|

|

|

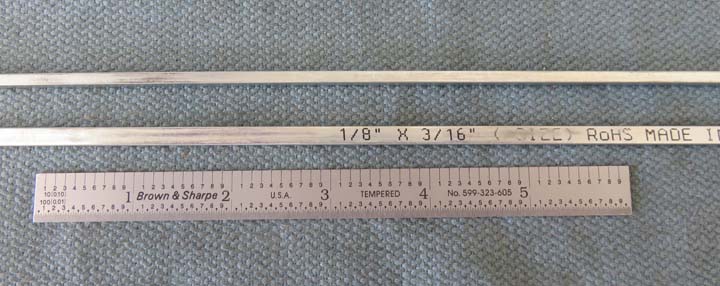

Here you can see I've got some steel key material that

measures the exact size I needed, 1/8" X 3/16". It seems McMaster Carr

has just about everything I needed which makes buying from them that

much easier. Now it's just a matter of cutting this material to length

later on.

|

|

Another thing I purchased from McMaster Carr was this chain. I bought 20

feet of #35 chain which should be enough for all my needs, and a master

link was included.

|

|

I didn't know exactly what else I might need so I bought a few different

types of links just in case they were needed because they were very

cheap.

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23 |