|

More

Component Parts Continued I went 3/4" inch deep

on the pocket, which is all I could go with the

type of end mill I was using. However, this should be more than enough

for this to work right. In case you were wondering about that funny

looking area on the chamfer, that's a casting flaw

that was in the aluminum before I machined it.

|

|

|

Here is what it looks like once it's placed inside the

pocket. When the adapter is permanently mounted to the shaft, a portion

of it will be sticking out once the safety doors are closed. Then the

guests will grab the hand wheel, place it over the square part of the

adapter and turn the gears. All this in the order to keep everyone safe.

|

|

|

The item that will be dispensed is something I think

people will want to see while the gears are turning. I plan on making a

window out of some clear plastic so everyone can see the progress of the

item as it makes it way across the threads. This should build the

anticipation as the clock is ticking.

The pencil line represents the size of the window that

I'll be cutting out and should be just the right size and location for

most everyone to see. Laying out the location was easy to do from the

back so I know it's in the right spot.

|

|

I transferred the location to the front as it will be easier to cut from

this side. After removing the 12" gear, I used a jigsaw for the cut and

it worked pretty good.

|

|

|

I had some leftover plastic sheet from another project

that I thought would work great for this. In fact, one dimension was

already finished so all I had to do was make one cut. All you do is

'score' the top surface a few times and then using your hands, snap the

piece in two. I like using something with a straight edge while scoring

and breaking, like these two pieces of wood the plastic is sandwiched

between.

|

|

|

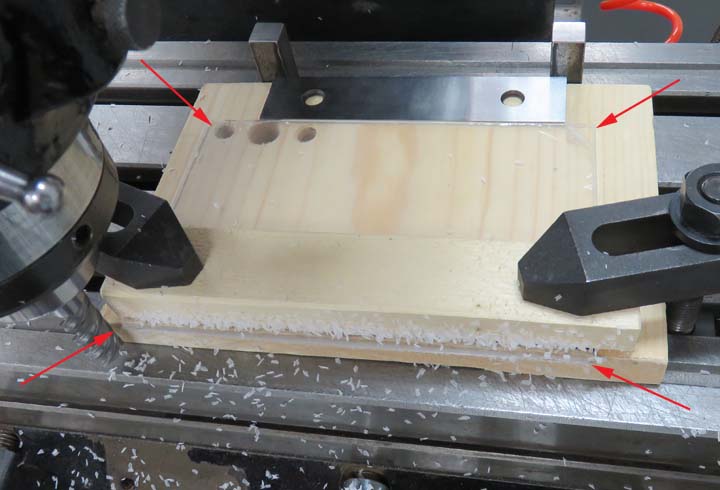

I wanted to machine the periphery to size (the arrows

show the corners) so I used my milling machine for this. Machining this

plastic is not as easy as it sounds, it tends to crack and melt onto

your cutter if you go to fast. Slowing down the RPM is key here and

taking your time.

|

|

|

To hold the plastic in place I'll be making a trim piece

out of aluminum. The thickness of the trim piece is .090" and will look

like the cardboard cutout on the right when finished. After cutting out

the cardboard template, I used a scribe to transfer the rough location

from the template of where I need to cut.

|

|

|

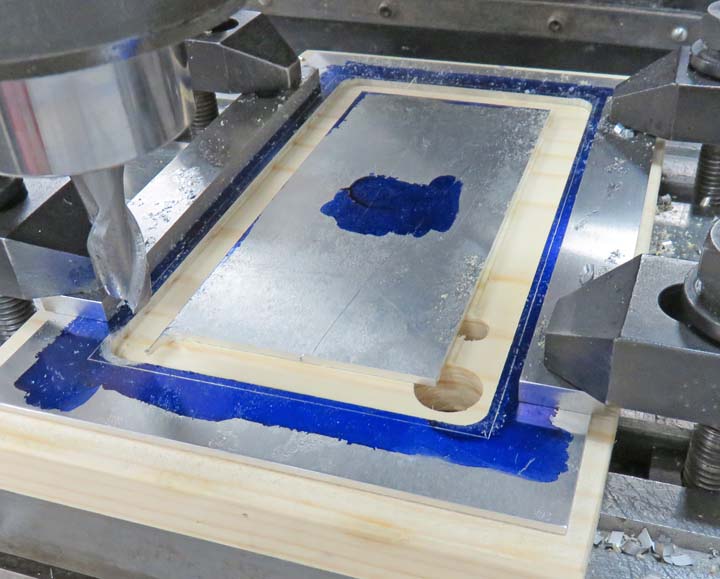

Cutting thin sheet is always a challenge with clamping

being the most important detail. After finding the center of my work

piece, I was ready to make some chips (aluminum chips that is).

|

|

|

I used a 3/4" end mill to cut with and stayed away from

my line by about 1/8". Notice the center of the aluminum sheet is still

resting on my wood tooling. Wood tooling works great for things like

this because it's easy to work with and is very cheap too.

|

|

I also cut a recess into the trim piece for the plastic to sit. This way

the plastic is trapped and won't move once it's fastened down.

|

|

To fasten it down with I'll be using six flathead screws. This was an

easy piece to make and should look nice when mounted on the plywood.

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23 |