|

Working With Wood Continued

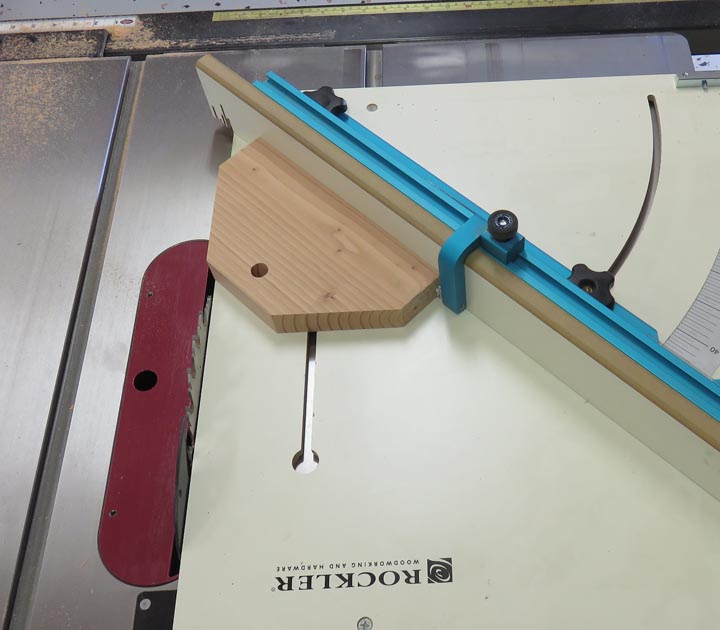

Now that the bushing holes are in, I'm going to cut some 45 degree

angles on the side pieces.

|

|

|

I wanted each angle to be exact and to have a

nice finish so I used my table saw and my cross-cut sled to skim each

edge. This only took a few minutes and worked out great.

|

|

|

|

Working With Metal

I'm going to make the bushings out of some leftover 5/8" diameter

round bar that was used on another project,

|

|

|

|

I made two for each scale. These are 1 3/4" long with a

reamed 3/8" diameter hole through them. These will get pressed into the

side pieces and then I'll use a pin that will locate through both

bushings.

|

|

|

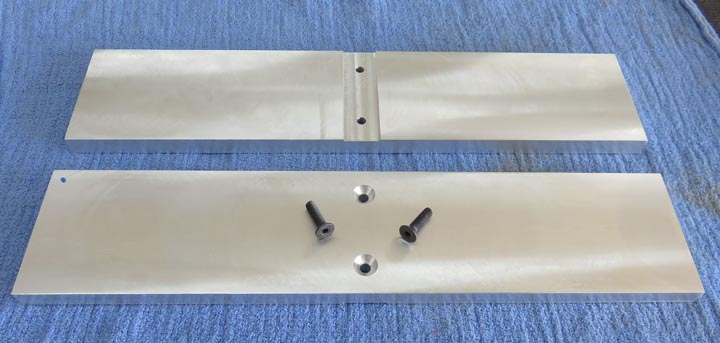

Here I'm cutting some 1/2' thick aluminum plate that will be used for

the balancing arm. My bandsaw made quick work of cutting these.

|

|

|

This was also leftover from a previous project and should work nicely

for this. The type of aluminum is 6061-T6, which is perfect for this

application.

|

|

|

I milled all six sides square, and here I'm cutting the ends to length

which will be 12.00" long exactly. The width is 3.0" wide.

|

|

|

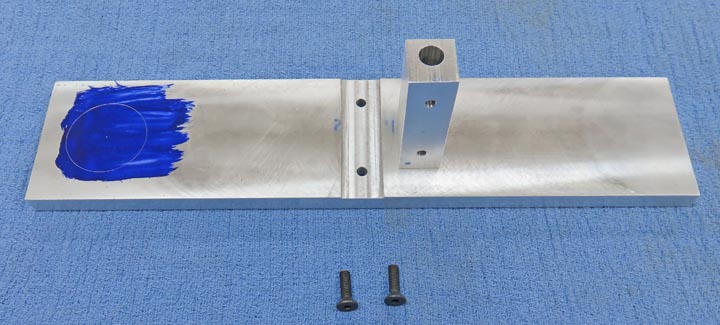

I milled a .750" wide slot by .050" deep that will be used to

locate a block

that will be used as a pivot point. The block will be held in place by

those two 10-32 screws.

|

|

|

|

The block is 3/4" X .800" tall, with a 3/8" diameter

hole that goes through. The blue layout dye is going to have a round

pocket, and if you look close you can see the layout lines that

represents a 1.500 diameter circle. I'll talk more about this later.

|

|

|

Here I'm using a 3/8" radius cutter to produce a full radius on the 3/4"

dimension. This radius will serve two things: first it has a nice rounded

surface so nobody gets hurt, and second, it just looks nicer.

|

|

|

|

1

2

3

4

5

6

7

8 |