|

Working With Metal Continued

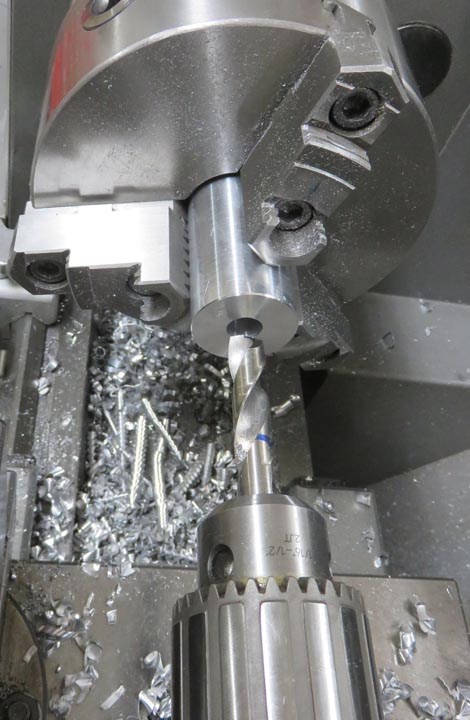

Then I turned them around and faced, chamfered and drilled them with a

1/2" drill by 1 3/4" deep (note the reference line on the drill).

|

|

|

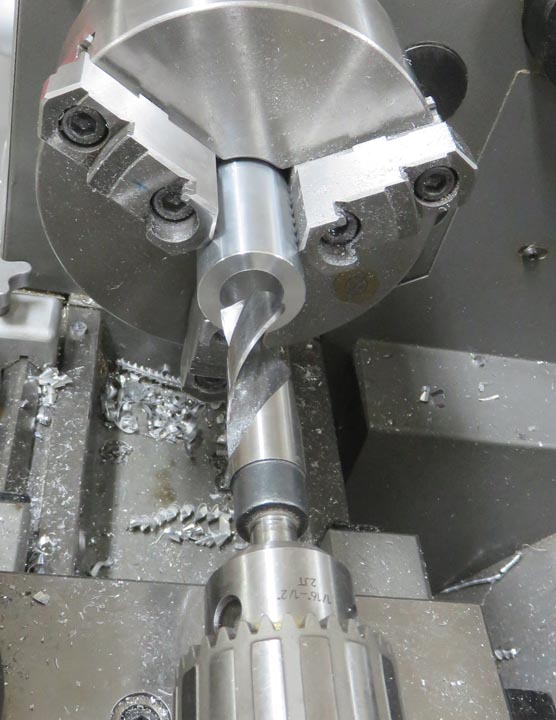

Next I used a 7/8" drill and went to the

same depth as above.

|

|

|

My dog Theo came out to visit me and wanted to play. So I took a break

and took him up on his offer.

|

|

|

Anyways, then I bored them out to 1.00" by 1 3/4" deep.

|

|

|

Last I made a counterbore that was 1 1/4" diameter by 1/8" deep and

chamfered both diameters.

|

|

|

Here you can see the flat bottom along with the counterbore. This

counterbore will be used for an end-cap that will be held in place by a

10-32 flathead screw.

|

|

|

|

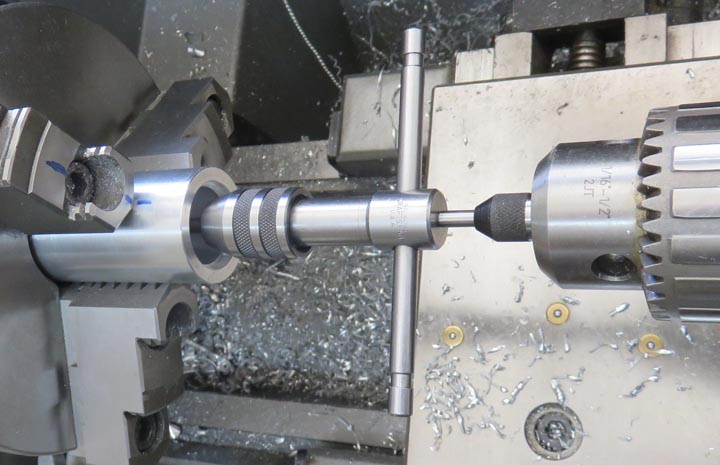

Here I'm drilling and tapping for the 10-32 threads. And

I'm keeping the tap straight using a spring loaded centering guide. At

this point, the main part of the cylinders are finished. Now I need to

make the end-caps.

|

|

|

|

Here I'm making the end-caps. First I faced the end,

drilled a 3/16" hole as deep as I could go (this is so I could make

several end-caps without drilling each one), chamfered for a flathead

screw, used the parting tool about half way through the part, switched

to a chamfer tool and did the inside and outside, switched back to the

parting tool and parted it off. This method worked well, it's just rinse

and repeat 12 times.

|

|

|

And there we go, I now have all the cylinders and end-caps finished.

|

|

|

|

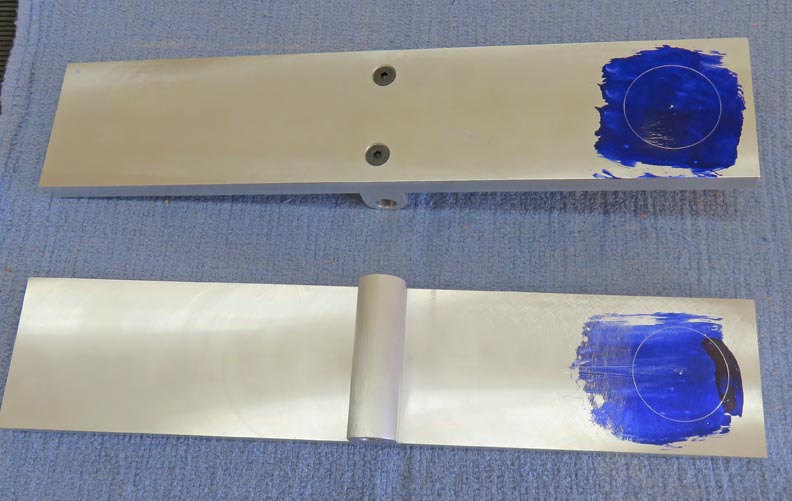

Now it's time to work on the balance bar. I'll need a

round pocket on one end for the cylinders. This pocket will be .100"

deep (just shy of 1/8"). However, by removing this amount of

material will throw the balance off slightly. To help offset this, I'm

going to make another pocket (of the same size) on the under-side but at

the opposite end. Nobody will see this other pocket so anyone that's

playing won't even know.

|

|

|

|

1

2

3

4

5

6

7

8 |