|

Working With Metal Continued

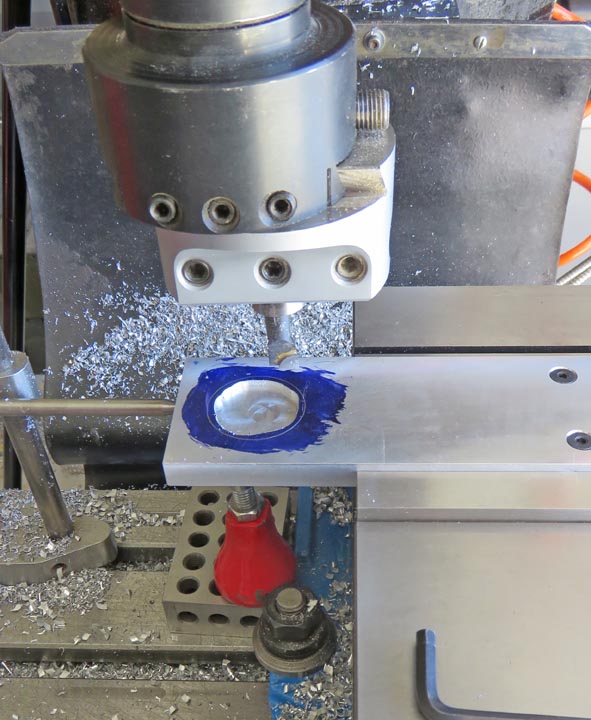

To make sure the bottom of the pocket is flat, I first

used and end mill and removed as much material as I could but stayed away

from the line. If you look close, you can see the pocket isn't round

(which is normal using this method). However, by using my boring head and

a boring bar, I can make the pocket round.

Now you might be asking, why don't I just use my boring

bar for the entire operation? Because a boring bar is made so it has

clearance at the bottom, with only the point touching your work first.

If I were to use the boring bar method only, there would be a series of

grooves every time I adjusted the boring head to cut larger.

|

|

|

|

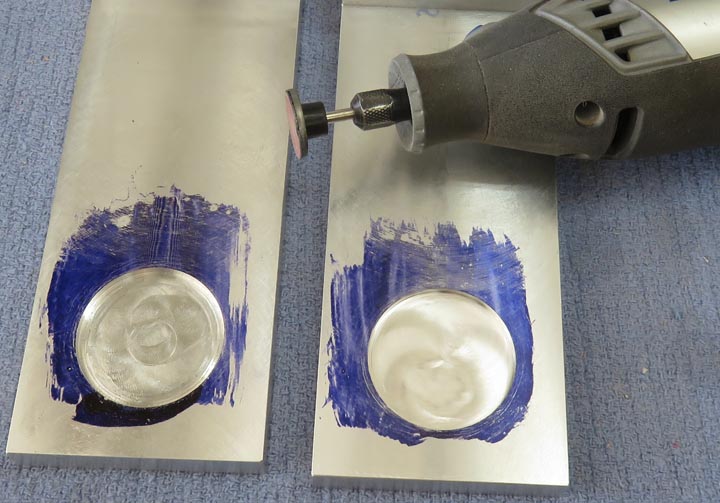

If you look close, you can see the endmill marks in the

pocket on the left. This is unavoidable but a necessary evil by doing it

this way. No big deal because those tool marks were quickly removed

using my Dremel and a sanding accessory.

|

|

|

|

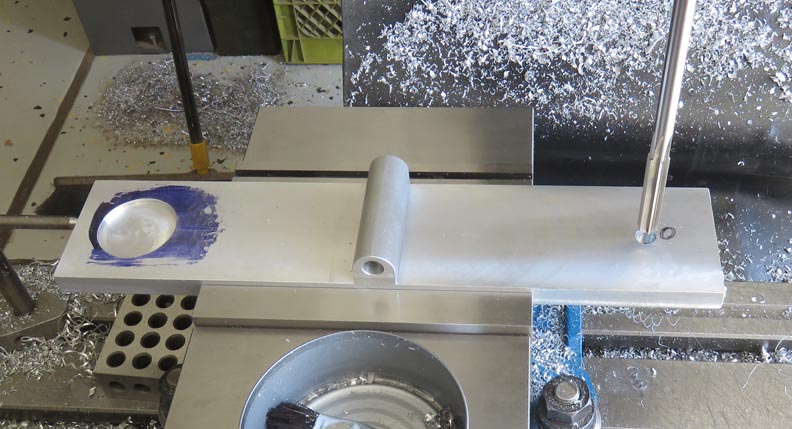

At the opposite end of the pocket, I'll be installing a 3/8"

diameter pin to help locate the gold bars. The reason for this is

because if you randomly placed the gold bar at the end of the balance

bar, this would throw off the center of mass and wouldn't work right. What I came

up with is to locate the gold bars on this pin so the center of mass

stays constant. The gold bars in turn will have a 3/8" diameter pocket

in the bottom of them. This way the players will be able to locate each

gold bar easily and they will be in the exact location, no matter which

way they are placed on the pin.

|

|

|

|

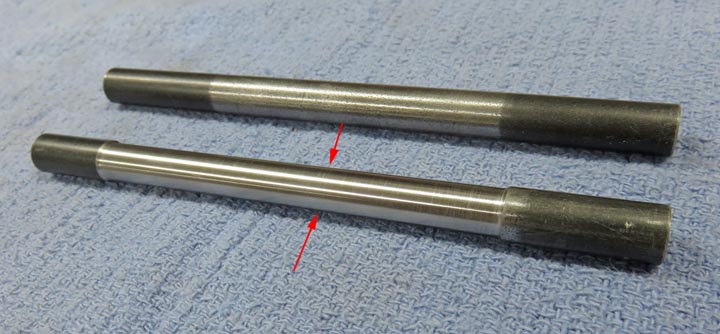

I'm using 3/8" hardened dowel pins for the pins. This way

they won't wear out and should last for years. I had to shorten the pins

by 1/4" using my lathe, which was really hard to do. The final length

for the dowel pins are 1/2" and will be pressed in.

|

|

|

I added some chamfers to all the sides of the balance bar. I gave the

ends a nice large chamfer, because chamfers make everything look better

:-]

|

|

|

|

As I was doing some testing, I noticed the dowel pin was

too heavy and nothing balanced any longer. To help off-set this, I added

some 1/4-20 flat head cap screws to the opposite end of the pins.

|

|

|

The side where the cylinders will sit is the side I added the flat head

screws to the underside. This worked pretty good but it's not perfect

yet, so

I'll have to revisit this later.

|

|

|

Here is what the top side looks like. It's getting closer but I did make

a couple of changes.

|

|

|

|

The first change I made was to reduce the pin diameter

the center only. By reducing the diameter by

a small amount (arrows), this allows the pin to work more freely with

less friction. Now the balance bar works much better, or with less drag

making it more sensitive.

|

|

|

|

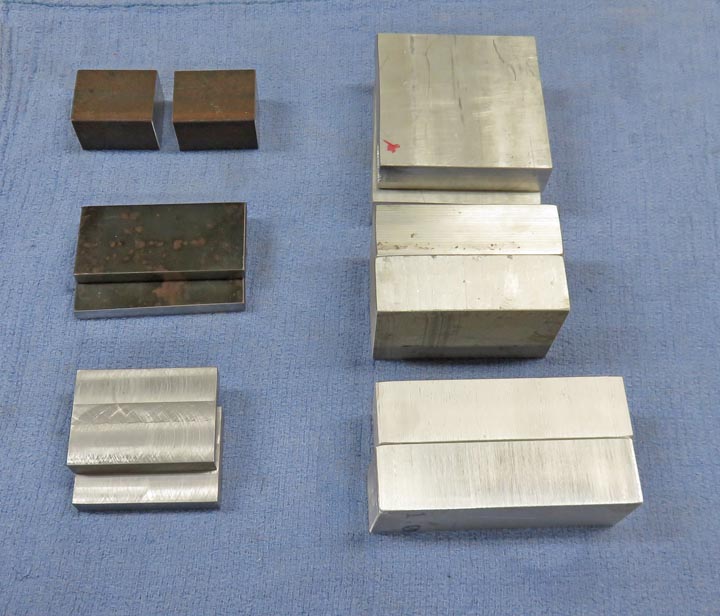

The pieces that you see below will become the gold bars.

The three on the left are steel and the others are aluminum. Once

they're painted, it will be hard to tell what material they are, but

that

won't really matter.

|

|

|

|

1

2

3

4

5

6

7

8 |